Diesel Particulate Filter (DPF) regeneration is a critical maintenance process for modern Volvo D13 engines. When your truck’s warning lights illuminate and performance drops, knowing how to force regen can save you thousands in downtime and repair costs.

This comprehensive guide walks you through the entire process, from understanding what regeneration is to executing it properly on your Volvo D13.

What is DPF Regeneration and Why It Matters

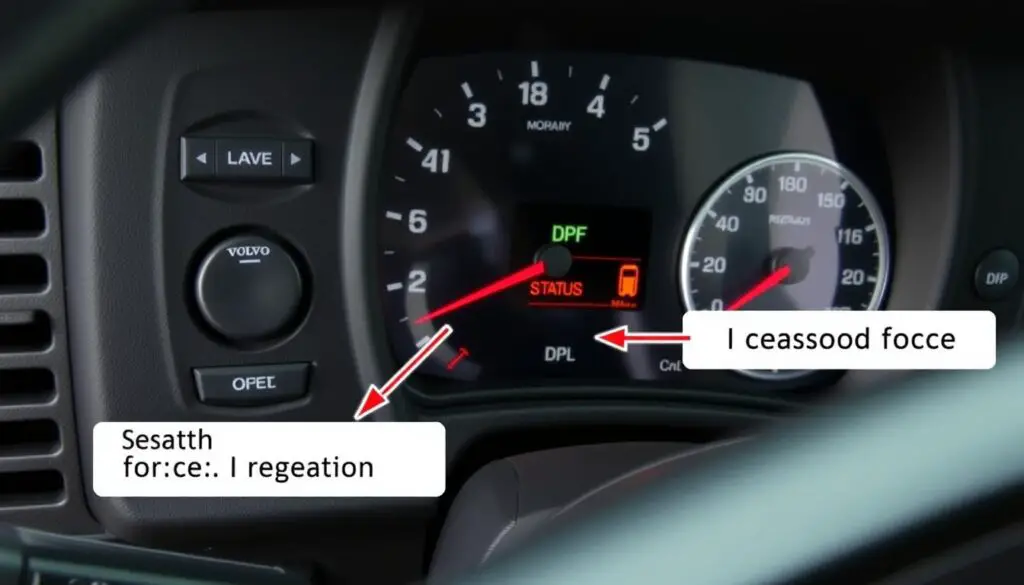

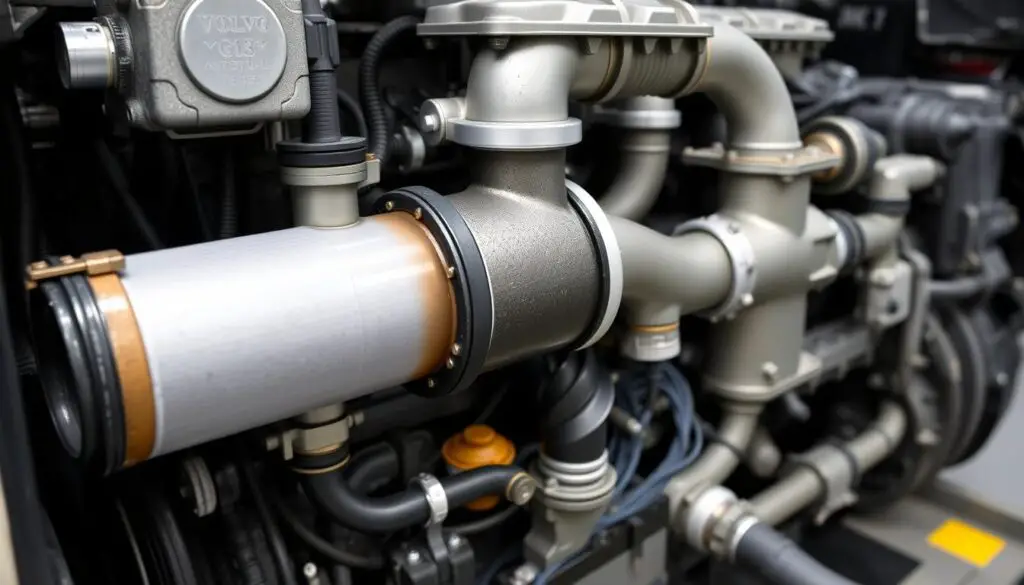

Volvo D13 DPF system components involved in the regeneration process

Regeneration is the process of burning accumulated soot in your Diesel Particulate Filter (DPF) to convert it into ash. Your Volvo D13 engine is designed to perform this automatically during normal operation, but certain conditions can prevent this from happening.

When soot levels become too high, your engine’s performance suffers dramatically. Ignoring the need for regeneration leads to severe consequences:

- Engine derates (reduced power and speed)

- Decreased fuel efficiency (up to 5-7% reduction)

- Check engine lights and dashboard warnings

- Potential for costly DPF replacement ($3,000-5,000)

- Increased risk of engine damage

Understanding when and how to force a regeneration cycle is essential for maintaining your Volvo D13’s performance and avoiding expensive repairs.

Prevent Costly DPF Replacements

Professional diagnostic tools allow you to monitor soot levels and perform forced regens before damage occurs. Avoid $3,000+ replacement costs with proper maintenance.

Prerequisites for Forced Regeneration

SAFETY WARNING: Always perform regeneration in a well-ventilated area away from flammable materials. The exhaust system reaches extremely high temperatures (over 1000°F/538°C) during this process.

Before attempting to force a regeneration cycle on your Volvo D13, ensure you meet these critical requirements:

Essential Requirements

- Engine at normal operating temperature (minimum 185°F/85°C)

- Fuel level at 25% or higher

- Parking brake engaged

- Transmission in neutral position

- Engine at idle speed

- No active critical fault codes

Recommended Tools

- Volvo VIDA diagnostic software or compatible scanner

- OTR Reset Tool (for older models without dashboard regen options)

- Heat-resistant gloves

- Fire extinguisher (safety precaution)

- Well-ventilated work area

Attempting to force regeneration without meeting these prerequisites can result in failed regeneration cycles or potential damage to your engine’s aftertreatment system.

Methods to Force Regen on Volvo D13

Depending on your truck’s year model and available equipment, you have several options to initiate a forced regeneration cycle. We’ll cover the most effective methods from simplest to most advanced.

Method 1: Dashboard Controls (2014+ Models)

- Ensure the truck is parked on a level surface with the parking brake engaged

- Start the engine and allow it to reach operating temperature

- Press and hold the Regeneration Button (typically marked with a filter symbol)

- Continue holding for 5-10 seconds until the regeneration indicator illuminates

- The display will show “Stationary Regeneration Active” when the process begins

- Allow the process to complete (typically 20-40 minutes)

- The dashboard will indicate when regeneration is complete

Note: If your dashboard doesn’t have a dedicated regeneration button, you’ll need to use one of the diagnostic methods described below.

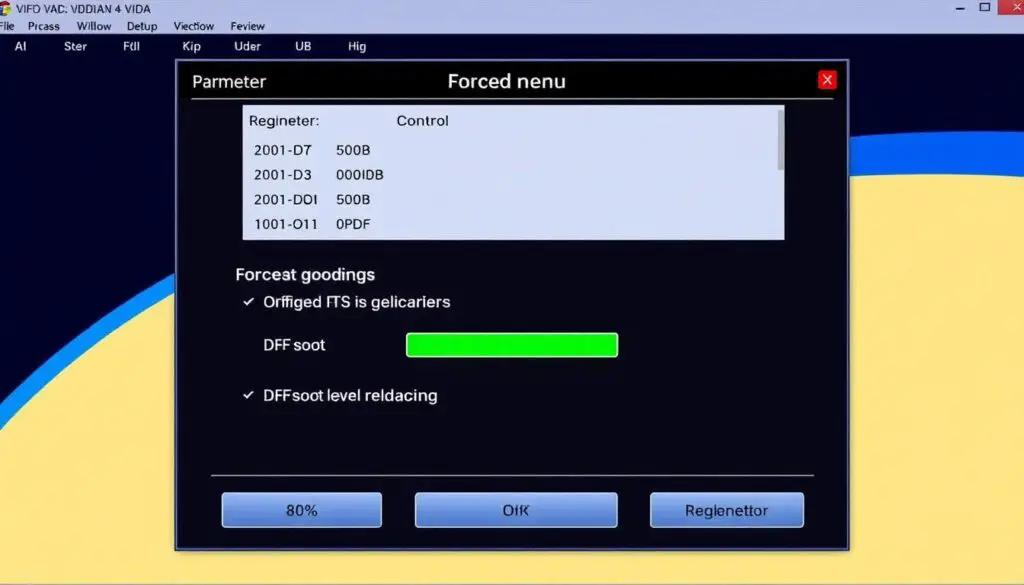

Method 2: VIDA Diagnostic Software

The Volvo VIDA diagnostic software provides the most comprehensive control over the regeneration process:

- Connect the VIDA interface to your truck’s diagnostic port

- Launch the VIDA software and establish communication with the ECM

- Navigate to “Service & Maintenance” → “Engine” → “Aftertreatment”

- Select “Stationary Regeneration” from the menu options

- Follow the on-screen prompts to initiate the regeneration cycle

- Monitor the soot level percentage and temperatures throughout the process

- Allow the cycle to complete fully (software will indicate completion)

Method 3: Aftermarket Diagnostic Tools

Specialized aftermarket tools like the OTR Reset Tool provide a simpler alternative to dealer-level diagnostics:

- Connect the diagnostic tool to your truck’s 9-pin diagnostic connector

- Power on the tool and select “Volvo” from the manufacturer menu

- Navigate to “Aftertreatment” or “DPF Functions”

- Select “Force DPF Regeneration” from the available options

- Confirm your selection when prompted

- The tool will communicate with your ECM to initiate the regeneration

- Monitor the process until completion (typically 20-45 minutes)

OTR Reset Tool Benefits

- One-time purchase vs. dealer visits

- Perform regens anywhere, anytime

- Reset fault codes and aftertreatment parameters

- Compatible with 2004-2013 Volvo D13 engines

- No special software knowledge required

Method 4: On-the-Road Regeneration

Optimal driving conditions for successful on-road regeneration

If stationary regeneration isn’t possible, you can attempt to trigger a regeneration while driving:

- Maintain a steady speed above 55 mph (88 km/h)

- Keep engine RPM above 1500 consistently

- Drive continuously for at least 20-30 minutes

- Avoid stop-and-go traffic or idle periods

- Monitor dashboard for regeneration indicator

Important: On-road regeneration is less reliable than stationary methods and may not work if soot levels are already too high or if fault codes are present.

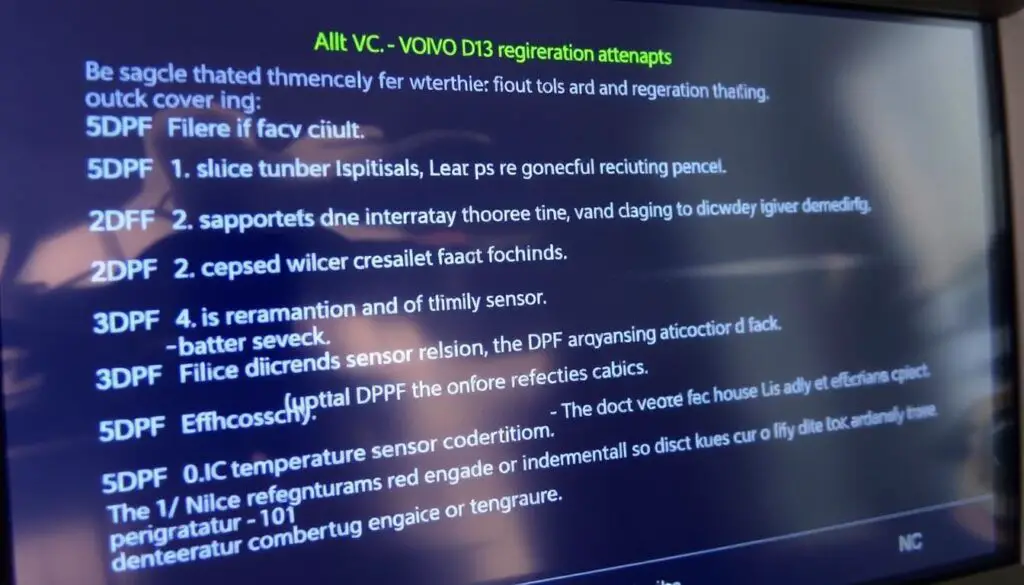

Troubleshooting Failed Regeneration

If your regeneration attempts fail, several common issues may be responsible:

Common Issues

- Insufficient exhaust temperatures

- Faulty temperature sensors

- Excessive ash accumulation (beyond regen capability)

- Hydrocarbon doser/7th injector malfunction

- DOC (Diesel Oxidation Catalyst) deterioration

- Exhaust leaks before DPF

- ECM software issues

Solutions

- Verify all sensors are reading correctly

- Check and clean the hydrocarbon doser

- Inspect for exhaust leaks and repair

- Professional DPF cleaning if soot levels exceed 80%

- Reset aftertreatment learned values

- Update ECM software if available

- Replace faulty components as needed

Expert Tip: If regeneration consistently fails despite troubleshooting, your DPF may have reached its ash capacity limit. Unlike soot, ash cannot be removed through regeneration and requires professional cleaning or filter replacement.

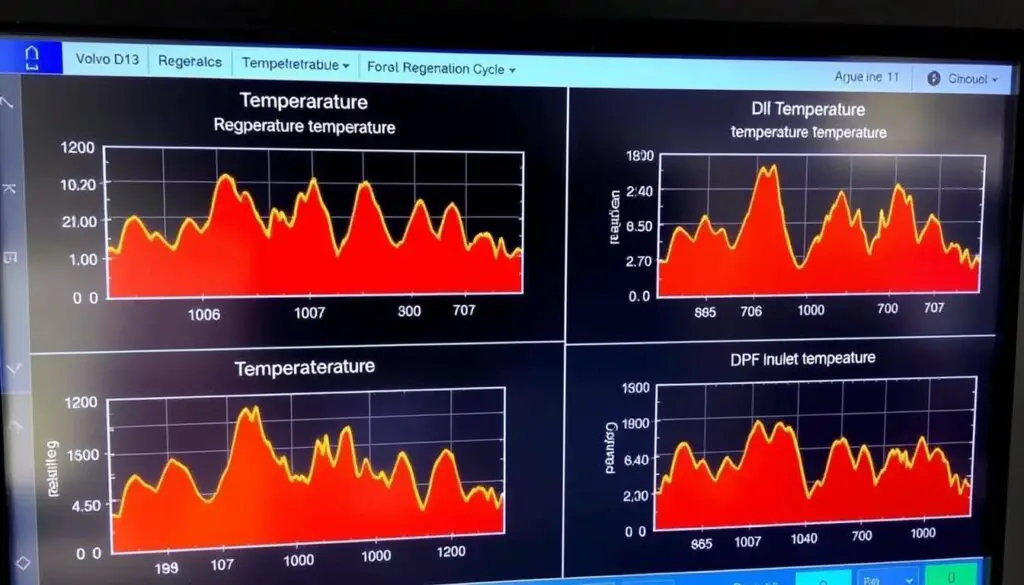

Post-Regeneration Best Practices

Monitoring key DPF health parameters after regeneration

After successfully completing a forced regeneration, follow these best practices to maintain optimal DPF performance:

- Verify Soot Reduction: Check that soot levels have dropped below 20% using your diagnostic tool

- Clear Fault Codes: Reset any regeneration-related fault codes that may have triggered

- Monitor Differential Pressure: Confirm the DPF differential pressure has returned to normal range (0.5-2.5 kPa at idle)

- Preventive Maintenance Schedule: Establish regular intervals for checking soot levels

- Driving Patterns: Incorporate more highway driving to promote passive regeneration

Recommended maintenance schedule for optimal DPF performance

“Regular monitoring and proactive regeneration can extend DPF life by up to 50% and prevent costly downtime. Most DPF failures occur because issues are addressed too late in the soot accumulation cycle.”

DPF Maintenance Checklist

- Check soot level every 2-3 weeks

- Perform forced regen when soot exceeds 45%

- Inspect for exhaust leaks quarterly

- Test hydrocarbon doser function annually

- Professional DPF cleaning every 200,000 miles

Frequently Asked Questions

Common questions about the DPF regeneration process

How often should I force a regeneration on my Volvo D13?

Ideally, you should only need to force regeneration when your truck’s ECM cannot complete the process automatically. For most operators, this means performing a forced regen every 2-3 months. However, if you notice your soot level consistently exceeding 45%, you may need to force regeneration more frequently or address underlying issues affecting the automatic regeneration cycle.

Can I damage my engine by forcing regeneration too often?

Forcing regeneration when not needed won’t directly damage your engine, but it does create unnecessary thermal stress on your aftertreatment components. The extreme heat during regeneration (over 1000°F/538°C) can reduce the lifespan of your DOC and DPF if performed excessively. It’s best to only force regeneration when soot levels exceed 45% or when recommended by your diagnostic system.

Why does my Volvo D13 need frequent regenerations?

Frequent regeneration needs typically indicate an underlying issue. Common causes include: excessive idling, short-trip driving patterns, engine performance issues (poor fuel atomization), exhaust leaks, or deteriorating aftertreatment components. If your truck requires regeneration more than once a month, have a qualified technician diagnose the root cause.

What’s the difference between active, passive and forced regeneration?

Passive regeneration occurs naturally during normal highway driving when exhaust temperatures are high enough to burn soot without additional fuel. Active regeneration is automatically initiated by your ECM when soot levels reach a threshold, injecting additional fuel to raise exhaust temperatures. Forced regeneration is manually initiated when the automatic systems cannot complete the process and requires diagnostic tools or dashboard controls.

Conclusion

A well-maintained DPF system ensures optimal engine performance

Knowing how to properly force regeneration on your Volvo D13 engine is an essential skill for any truck owner or fleet manager. By following the procedures outlined in this guide, you can maintain optimal DPF performance, prevent costly downtime, and extend the life of your aftertreatment system.

Remember that forced regeneration should be viewed as a maintenance procedure, not a permanent solution to underlying issues. If you find yourself needing frequent regenerations, investigate the root causes with the help of a qualified technician.

With the right tools and knowledge, you can take control of your Volvo D13’s DPF maintenance and keep your truck running at peak performance for years to come.