Volvo Cars has officially begun production of its fully electric EX90 SUV at its manufacturing facility outside Charleston, South Carolina. This milestone marks a significant advancement in Volvo’s electrification strategy and reinforces the company’s long-term commitment to the U.S. market. The first customer-bound EX90, painted in striking Denim Blue, recently rolled off the production line and is destined for a U.S. customer in the second half of 2024.

The Charleston Manufacturing Facility: Volvo’s U.S. Production Hub

Volvo’s Charleston plant, which opened in the summer of 2018, represents the company’s first manufacturing facility in the United States. Located just outside one of America’s most historic cities, this state-of-the-art facility has been significantly expanded to accommodate production of the fully electric EX90 SUV alongside the existing S60 sedan.

The plant currently has an installed production capacity of 150,000 vehicles annually, positioning it as a crucial component in Volvo’s global manufacturing network. This capacity makes the Charleston facility a key player in meeting U.S. market demand while reducing dependency on imports from overseas plants.

In recent years, Volvo has made extensive investments totaling $1.3 billion in the Charleston facility. These investments have funded significant expansions and upgrades to the body shop and paint shop, along with the addition of a state-of-the-art battery pack production line essential for EX90 manufacturing.

The Charleston plant’s expansion represents Volvo’s strategic approach to localizing production for the U.S. market. By manufacturing vehicles domestically, Volvo can better adapt to specific U.S. market demands while mitigating the impact of tariffs on imported vehicles.

This manufacturing strategy aligns with Volvo’s broader goals of reducing carbon footprint through localized production and responding more efficiently to regional market preferences. The facility employs thousands of skilled workers from the surrounding communities, contributing significantly to the local economy.

EX90 Production Specifics: Building Volvo’s Electric Flagship

The Volvo EX90 represents a paradigm shift for the company as it’s the first Volvo vehicle powered by core computing technology. This technology enables advanced safety features and establishes a new benchmark for Volvo’s commitment to passenger protection and accident prevention.

Based on Volvo’s next-generation, born-electric EV technology platform, the EX90 offers an impressive fully electric range of up to 300 miles. The vehicle is designed to be the safest Volvo car to date, featuring next-generation passive and active safety technology powered by a comprehensive suite of sensors and advanced software.

Experience the Future of Electric Mobility

The Volvo EX90 represents the pinnacle of Volvo’s electric vehicle technology, manufactured right here in the United States. Discover how this revolutionary SUV combines Scandinavian design with American craftsmanship.

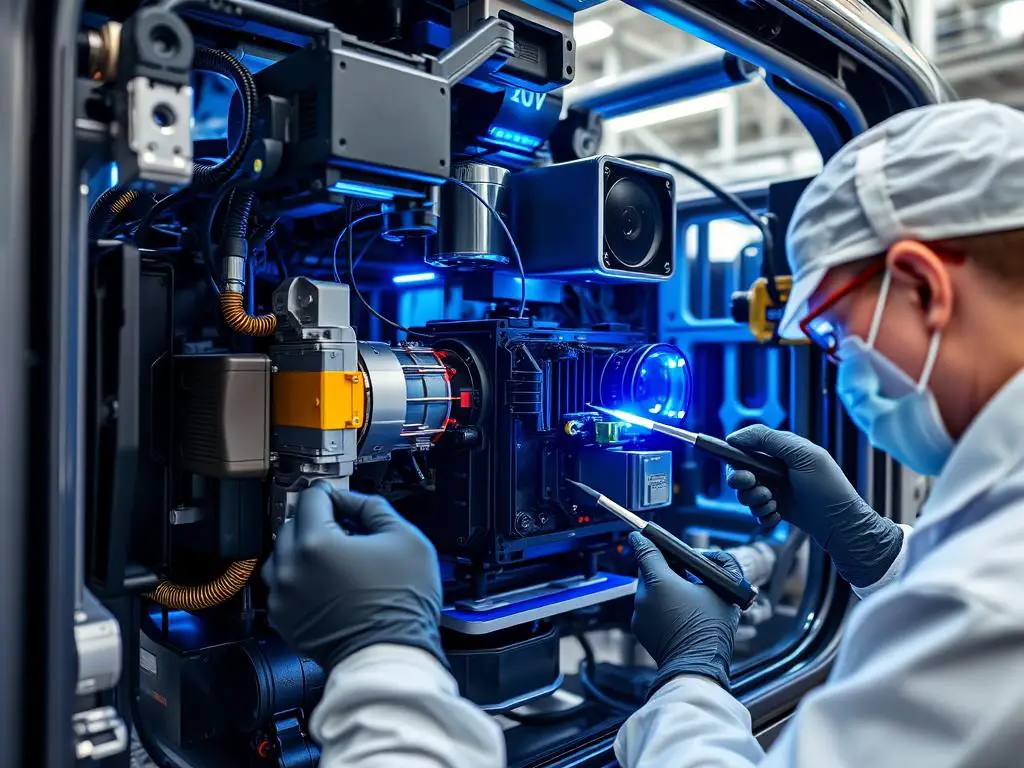

Production of the EX90 involves sophisticated manufacturing processes that integrate Volvo’s commitment to quality, safety, and sustainability. The vehicle’s assembly incorporates advanced robotics alongside skilled human craftsmanship to ensure precision in every component.

The EX90’s true seven-seater configuration makes it an ideal family vehicle, offering ample space, versatility, and comfort. Rooted in Scandinavian design principles, the EX90 features modern proportions that optimize safety, efficiency, and aesthetics while maintaining Volvo’s distinctive styling language.

U.S. Market Strategy: Expanding American Production

Volvo’s decision to produce the EX90 in South Carolina reflects a broader strategy to expand its manufacturing footprint in the United States. This approach allows the company to better meet the specific demands of American consumers while navigating the complexities of global trade policies.

The company has announced plans to bring additional vehicles to the South Carolina facility, including the bestselling XC60 midsize SUV starting in late 2026. This expansion reinforces Volvo’s commitment to localizing production and creating a robust manufacturing presence in the United States.

Volvo’s U.S. manufacturing strategy also addresses the impact of tariffs on global imports. By producing vehicles domestically, Volvo can avoid the significant tariffs that would otherwise apply to vehicles imported from its facilities in Sweden, Belgium, and China.

This regionalization effort allows Volvo to better respond to market-specific demands while maintaining the global quality standards that define the brand. The approach demonstrates Volvo’s adaptability in an evolving global automotive landscape and its commitment to the American market.

Volvo’s U.S. manufacturing footprint centered around the Charleston facility

“The fully electric Volvo EX90 is the start of a new era for Volvo Cars – a new era for safety, sustainability and human-centric technology. The EX90 is proudly manufactured in the USA and reflects our long-term commitment to our people in South Carolina and the broader US market.”

Technology and Innovation: Core Computing and Software Updates

The EX90 represents a technological leap forward as Volvo’s first vehicle powered by core computing technology. This advanced system enables a new generation of safety features and creates a platform for continuous improvement through over-the-air software updates.

The EX90 comes equipped with a powerful core system that remains constantly connected, allowing for improvements over time through software updates. These updates are delivered by Volvo’s software engineers, enabled by AI, and informed by real-time data collection to continuously enhance vehicle performance and features.

The vehicle’s advanced safety systems are powered by a comprehensive suite of sensors, including LiDAR, cameras, and radar. These systems work in concert with sophisticated software to create what Volvo describes as an “invisible shield of safety” around the vehicle.

This technology integration represents a significant advancement in Volvo’s approach to vehicle architecture, moving from distributed electronic control units to a centralized computing system that can be continuously improved and updated throughout the vehicle’s lifecycle.

Sustainability in Production: Environmental Considerations

Volvo’s approach to manufacturing the EX90 incorporates significant sustainability initiatives aligned with the company’s broader environmental goals. The Charleston plant has implemented numerous measures to reduce its environmental footprint while producing this next-generation electric vehicle.

The facility utilizes renewable energy sources where possible and has implemented energy-efficient manufacturing processes to minimize carbon emissions. Water conservation and recycling systems further reduce the environmental impact of vehicle production.

These sustainability initiatives reflect Volvo’s commitment to responsible manufacturing practices and complement the environmental benefits of the EX90’s all-electric powertrain. By producing electric vehicles in facilities designed with sustainability in mind, Volvo creates a more comprehensive approach to reducing automotive environmental impact.

The Future of Volvo Production in the United States

Volvo’s expansion of production at its Charleston facility represents a significant investment in the company’s future in the United States. With the EX90 leading the way, followed by the planned addition of the XC60, Volvo is creating a robust American manufacturing presence that will shape its strategy for years to come.

The company’s commitment to the U.S. market extends beyond manufacturing to include a network of 281 dealerships across 47 states, creating a comprehensive ecosystem for sales, service, and support. This extensive presence reflects nearly 70 years of Volvo operations in the United States.

As Volvo continues its transition toward an all-electric future, the Charleston plant will play an increasingly important role in producing vehicles tailored to American preferences and requirements. The facility’s capacity and capabilities position it as a cornerstone of Volvo’s global manufacturing strategy.

The production of the EX90 in South Carolina marks not just the manufacturing of a new vehicle, but the beginning of a new era for Volvo Cars – one defined by electric mobility, advanced technology, and a strengthened commitment to American manufacturing. As the first customer deliveries begin in the second half of 2024, the EX90 will showcase both Volvo’s vision for the future and the capabilities of its American production facility.

Ready to Experience the Volvo EX90?

The future of electric mobility is being built right here in America. Reserve your Volvo EX90 today and be among the first to experience this revolutionary electric SUV manufactured at Volvo’s state-of-the-art South Carolina facility.