The type of Volvo truck instrument cluster problems that you might be facing have a direct relationship with a few of its associated components. You may experience complete failure from electrical and solder faults or certain intermittent functionality due to loose connections. Issues also include specific gauge failures and illumination problems that could be caused by faulty LEDs or power issues.

Each of these problems requires careful inspection and troubleshooting in different ways. Not to mention, how it’s often too complicated to be handled on your own.

But before you call in a professional, there are some basics to check out yourself and in this guide, I plan to help you with that!

Common Volvo Truck Instrument Cluster Problems

If you try to find what are common problems with Volvo trucks, instrument cluster errors ought to be on that list.

Volvo trucks, especially with models such as the Volvo VNL 730 D13 iShift, often face problems with their instrument clusters. And afterwards, it can cause a lot of inconvenience. If not taken care immediately, it might even pose safety risks.

Now what are the symptoms of a faulty instrument cluster that anyone should initially look for?

The common symptoms of a faulty instrument cluster include Erratic gauge readings, blank or error-filled displays, persistent or absent warning lights, intermittent functionality, and unexpected power loss.

Below I will list down different instrument cluster problems and suggest some general repair procedures to try.

1. Complete Cluster Failure

Now it’s likely that issues with your Volvo’s instrument cluster is stemming from more than several sources. One common cause is poor electrical connections. Especially at the power connector on the instrument cluster board.

What happens when these connections are not secured properly? Well, usually they will lead to various malfunctions in the display and readings.

One more potential cause is faulty solder joints. Over time, these joints will develop some cracks or might become loose. And this ends up disrupting the electrical flow. As a result, the instrument cluster fails or starts behaving erratically.

Problems may also arise from the main wiring harness. You see, this harness is quite important for delivering power and signals to the instrument cluster. And that’s why if there’s any damage or wear in the wiring, it will lead to disruptions in the instrument cluster’s performance.

Grounding problems fall under this category as well. This is because bad ground can prevent the instrument cluster from functioning the right way.

Last but not least, the instrument cluster module (ICM) itself could be faulty. For the mechanism to work properly, this module plays a responsible part in controlling the display and processing the data it shows. That’s why if the ICM is defective, it will cause inaccurate readings. Or even worse, complete failure of the instrumental cluster.

To address a complete cluster failure, you should follow these steps:

- Start With Checking Electrical Connections: Make sure you inspect and secure all electrical connections to the instrument cluster. Pay special attention to the power connector.

- Ensure There’s Proper Grounding: You should keep the grounding points clean and firmly connected. This way there won’t be any grounding issues.

- Check The Solder Joints: Look at the solder joints on the instrument cluster board to find out any signs of damage. It could also be corrosion. Consider re-soldering any suspect joints.

- Go Ahead With Diagnostic Testing: If the problem is still there, consider performing diagnostic testing on the main wiring harness. You should check for continuity and for faulty harness you need to replace it.

- Replace the Instrument Cluster Module: Finally, if none of the above steps resolve the problem, you should think about replacing the instrument cluster module (ICM) with a known good unit.

2. Intermittent Cluster Functionality

One of the main symptoms of Volvo truck’s intermittent cluster functionality is that the gauges and message screen work alternatingly. This means that at times, you might notice that they function accurately. But then again, sometimes, they fail to display any information at all.

There’s another common scenario of these problems temporarily resolving on their own. But after you cycle the ignition or perform other random actions, such as tapping on the dashboard, the problem reenters the equation.

Now there are many factors that could be causing these intermittent issues. One very likely cause is loose connections in the wiring harness. Again, this part malfunctioning can disrupt the flow of information to the cluster.

In this case also, poor contact points within the instrument cluster itself can lead to inconsistent functionality. Rarely, it also happens that there are some data communication issues within the control modules. As a result, it stops the necessary information from reaching the cluster consistently.

To fix these faults try:

- Reconnecting Loose Connections: Make sure to also clean all connectors and contact points, to ensure they are seated firmly.

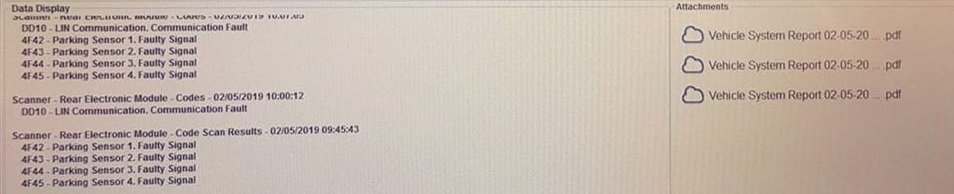

- Fixing Data Communication Errors: If securing the connections doesn’t resolve the problem, the next step is to use diagnostic tools to check for any data communication problems. This usually requires professional handling.

3. Specific Gauge Failures

Certain gauges, such as the speedometer or tachometer, may suddenly stop working. While others continue to work quite normally. This can also lead to errors with the instrument cluster of Volvo trucks.

It’s also true that the inconsistency can be hard to determine and pretty problematic. Simply because you may get accurate readings from some gauges but not from others. And that’s why, you may notice inconsistent or fluctuating values.

This will make it quite challenging to completely rely on your instrument cluster for correct information about your Volvo’s conditions.

There are more than a few factors that could be responsible for these symptoms. Let’s start with faulty gauge motors, something that can instantly prevent the gauges from functioning correctly. The next potential cause could be a damaged printed circuit board (PCB).

I am on the same page as PCBNet about the signs of a damaged PCB. Things like power cutting out sometimes, the board getting too hot and leaving burn marks, physical damage you can see, and circuits not connecting properly, they all point to quickly checking the PCB.

You will find this part within the instrument cluster. Also, note that problems with the sensors or wiring related to the specific gauge could also cause inconsistent readings. You should also consider checking the air suspension system, particularly the airbags in the Volvo trucks.

Here’s how you can try to figure out the exact problem and the appropriate solution.

- Diagnose Affected Gauge Motors: If you find that the gauge motors are not working properly, consider replacing them. You also want to make sure they are receiving the correct power and signals

- Replace Printed Circuit Board (PCB): Check for any visible damage or burnt components within the PCB inside the cluster. If you find any problem, replacing the PCB should restore proper function.

- Replace Faulty Sensors and Wiring: Look for signs of wear, damage, or disconnections within the sensors and wiring. You must replace faulty sensors and fix damaged wiring to resolve the issues correctly.

4. Illumination and Backlight Issues

Let’s say you are facing problems with the illumination and backlights in your vehicle’s instrument cluster. The first common symptom to look for is cluster backlights failing to illuminate completely.

As a result, the dashboard gets completely dark, and it becomes difficult to read important information. For example, the speed, fuel level, and engine warnings.

It is also possible you are facing dim or flickering illumination. This can get particularly severe at night or in low-light conditions. Make sure you have checked for any LCM problems that could be apparent with the Volvo truck.

Burnt-out or faulty LEDs within the instrument cluster are usually the culprit. These LEDs have a limited lifespan. And so, it can fail over time. It can also be the power supply not delivering the correct voltage.

Bad connections or faulty solder joints triggering the backlight circuit can also be to blame.

To fix illumination and backlight issues in your Volvo truck’s instrument cluster, follow these steps:

- Test and Replace LEDs: If you find any burnt-out or faulty LEDs within the cluster, replace them as soon as possible.

- Verify Power Supply: The power supply circuit should provide a stable voltage to the backlights. Restore any fluctuations or interruptions in power.

- Re-solder Connections: For any loose or broken connections, you need to re-solder it with the help of a professional.

Wrapping Up

Facing Volvo truck instrument cluster problems can get really frustrating. However, it’s all about going into their root causes and looking for potential solutions.

Keep in mind that despite trying your best, you may still need professional assistance as problems related to the instrument cluster could be minor but also major given how severe the situation is.

I’ll be back with more such guides in future, take care!