Quick, clear guidance for drivers who face sudden stalling at idle or at a light. This intro outlines common causes and practical checks in plain language.

Stalling at a stop often traces to a low idle setting, extra load from an A/C compressor or a strained alternator, or a rich or lean fuel mix. Low charging voltage from a weak battery can pull idle down and disrupt ignition or injector timing.

Start with basic checks: listen for the key-on fuel pump buzz, measure charging voltage (a healthy system reads about 13.5–14.5 V at idle), and note any load when the A/C cycles. These steps narrow the likely cause fast.

If a quick check points to deeper engine or electrical issues, follow the diagnostic sequence in this guide. For an in-depth look at related fuel and pump issues, see this write-up on volvo stalling and fuel pump diagnostics.

Key Takeaways

- Low idle, accessory load, or a bad fuel mix are common culprits.

- Check charging voltage at idle; aim for 13.5–14.5 volts.

- Listen for the fuel pump buzz and inspect spark and injector signals.

- Small maintenance lapses can escalate into drivability problems.

- Follow a stepwise diagnostic flow before replacing parts.

Common Volvo Stalling Scenarios and What They Mean

Spotting whether a stall happens at idle or at speed narrows down the fault fast.

Stalling at a stop or idle often means an idle speed set too low, an A/C compressor dragging the engine, or an unstable fuel mix. Unmetered air or a dirty throttle body can upset idle and let the engine die when the car slows.

Stalling while driving usually signals a sudden loss of spark from an ignition fault or a bad crankshaft position sensor. A roadside spark check during safe cranking helps separate an ignition issue from fuel delivery.

Electrical load and low voltage occur when the alternator recharges a weak battery. That extra draw can pull system voltage down, upset idle control, and cause a stall while accessories run.

- Listen for the key-on fuel pump buzz; silence points at pump, fuse, or relay faults.

- Map symptoms — A/C-related stalls point to compressor load; dim lights hint at charging issues.

- Safety first — switch on hazards, coast to the shoulder, then attempt a restart or scan.

Why Your Volvo Stalls When You Stop + How to Fix It

Begin diagnostics at the fuel tank and work forward through the delivery path. Listen for a brief key‑on fuel pump buzz at the tank; no buzz often means a dead pump, blown fuse, or failed relay. If the engine cranks and has spark but no pressure, suspect the pump and plan replacement rather than temporary fixes.

Fuel delivery and filters

Verify fuel at the rail and replace an overdue fuel filter. A clogged filter can starve the engine and cause idle problems. On models with both in‑tank and main pumps, inspect the in‑tank sock so debris does not foul the main pump.

Failing pump — roadside tips

A light tap on a failing external pump can sometimes free it for a short run. Treat this as a temporary measure and arrange prompt replacement of the faulty pump and any compromised in‑tank parts.

Ignition and sensor checks

Check plugs and coils for wear or cracks and evaluate the ignition switch if accessories flicker. Scan for codes and test the crankshaft position sensor, throttle position, MAF and oxygen sensors for consistent live data.

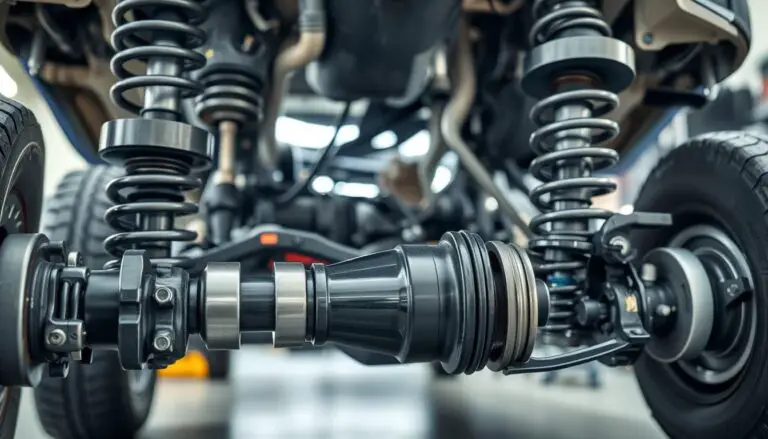

Airflow, charging and idle control

Inspect the air filter and catalytic for restrictions. Measure charging voltage at idle and aim for 13.5–14.5 volts so coils and injectors perform correctly. Clean the throttle body, verify idle control components, and apply ECM updates as needed.

Practical note: For a focused read on a V70 that starts then dies, see this brief fuel pump and restart guide.

Preventing Future Stalls with Smart Maintenance

Routine care for filters, spark parts, and intake components cuts the chance of an unexpected stall. A steady service cadence keeps combustion consistent and reduces load-related idle dips.

Service cadence: scheduled filter, plugs, and air care

Replace the fuel filter at factory intervals and fit fresh plugs on schedule. Clean or swap the engine air filter when it looks dirty.

These steps keep fuel flow and air metering stable. That lowers the risk of misfire and stalling during idle or when the engine faces extra load.

Pro diagnostics: when to book a specialist

If intermittent stalling or odd sensor readings persist without clear codes, arrange a professional scan. A Volvo specialist can check ECM logic, verify fuel pressure, and test the ignition system under load.

“Many drivability issues clear with a software update or targeted sensor test rather than part swaps.”

| Service | Typical interval | Primary benefit |

|---|---|---|

| Fuel filter | Every 30k–60k miles | Stable fuel pressure, fewer delivery issues |

| Spark plugs & coils | Every 30k–100k miles (model dependent) | Reliable ignition, fewer misfires |

| Engine air filter | Every 12k–30k miles | Clean airflow, correct air/fuel mix |

- Inspect vacuum lines and intake clamps often; small leaks cause mixture swings.

- Ask shops about ECM updates; they fix known causes without extra parts.

- Log maintenance times so a trend ties a new issue to recent work or wear.

Conclusion

A short, methodical test plan cuts diagnosis time and limits needless parts swaps. Listen for the pump at key‑on, confirm spark, and check charging volts before replacing components.

If the fuel pump is silent or pressure is zero, a tap may get the car running briefly. Treat that as a temporary measure and plan a proper pump and in‑tank filter sock replacement.

Check the ignition and crank position sensor when combustion stops while driving. Keep intake and exhaust clear, scan the ECM, and update software when available. A steady, prioritized approach finds the cause and makes the vehicle reliable again.

FAQ

What common reasons cause a Volvo to stall at a stop or while idling?

Low idle speed, an overloaded A/C compressor, or a rich/lean fuel mixture often causes stalls at idle. A dirty air filter, clogged fuel filter, or malfunctioning idle control valve can let the engine lose RPM. Inspect intake and fuel delivery first, then check ignition and sensors if problems persist.

How can a failing fuel pump present itself and what quick checks help diagnose it?

A failing pump may cause rough idle, loss of power, or no-start conditions. Listen for the fuel pump buzz at key-on, check fuel pressure with a gauge, and try a light tap on the in‑tank module as a temporary test. Replace the pump when pressure falls below specifications or when intermittent operation appears.

Which ignition components should be checked when the engine cuts out while driving?

Begin with spark plugs and ignition coils, then inspect the ignition switch and wiring. A loss of spark often results from worn plugs, failing coils, or a faulty crankshaft position sensor that stops timing signals. Swap parts or scan live data to isolate the fault.

What sensors commonly cause stalls and how are they tested?

Crankshaft position sensor, throttle position sensor, MAF (mass air flow), and oxygen sensors can trigger stalling. Use an OBD-II scanner to read trouble codes and monitor sensor data while the engine runs. Replace sensors that show erratic or out-of-range readings.

Could the charging system or battery cause intermittent stalling?

Yes. A weak battery or failing alternator can allow voltage to drop under electrical load, pulling idle down and causing stalls. Test the system: idle voltage should read about 13.5–14.5 volts with engine running. Repair alternator or replace a weak battery as needed.

How does a clogged catalytic converter or dirty air filter affect stalling?

A blocked catalytic converter raises exhaust backpressure and chokes the engine. A very dirty air filter restricts intake airflow. Both conditions upset combustion and can cause stalls at low RPM. Replace clogged filters or test exhaust flow for restriction.

When should I scan the ECM and consider software updates?

Scan whenever stalls are intermittent, when multiple sensors show faults, or when repairs don’t fix the issue. ECM updates from a Volvo dealer can resolve known software-driven idle or fuel-control problems. Always record codes before reprogramming.

What preventive maintenance reduces the risk of stalling?

Follow scheduled replacement of fuel filters, spark plugs, and air filters. Keep fuel injectors clean, ensure battery and charging health, and service the idle control and throttle body. Regular maintenance catches wear before it causes drivability issues.

When is it time to see a Volvo specialist for intermittent stalls?

If scans show ECM faults, if stalls continue after basic checks, or when electrical or sensor issues are intermittent and hard to replicate, book a Volvo technician. Specialists have model-specific diagnostic tools and software access to pinpoint complex faults.

What immediate safety steps should I take if a stall happens while driving?

Keep calm, signal, and coast to the shoulder if possible. Turn on hazard lights, shift to neutral, and attempt a restart only when safe. If the vehicle won’t restart, call for roadside assistance rather than attempting risky roadside repairs.